NAS1102 CSK screws are a staple within motorsport engineering, chosen for their high-strength properties and precise manufacturing standards. These aerospace-grade fasteners feature a 100° countersink angle and are manufactured from alloy steel with a tensile strength exceeding 160,000 PSI (1100MPa).

Key features of NAS1102 screws include:

- High-quality alloy steel construction ensuring durability and reliability

- Precise manufacturing tolerances for consistent fitment

- 100° countersink angle for optimal load distribution

Engineers particularly value these fasteners for their reliability in high-stress applications and their ability to maintain joint integrity under dynamic loads. The 100° countersink angle provides excellent load distribution while ensuring a flush finish, crucial for aerodynamic surfaces.

Key Benefits of Countersunk Screws

- Flush Surface Finishing: Allows fastener heads to sit flush with or below the surface level, creating a smooth, flat finish, enhancing aesthetics.

- Improved Safety: Eliminates protruding screw heads that could catch on clothing or cause injury.

- Aerodynamic Performance: Reduces drag in applications where air or fluid flow is critical

- Stress Distribution: Helps distribute stress more evenly around the fastener head

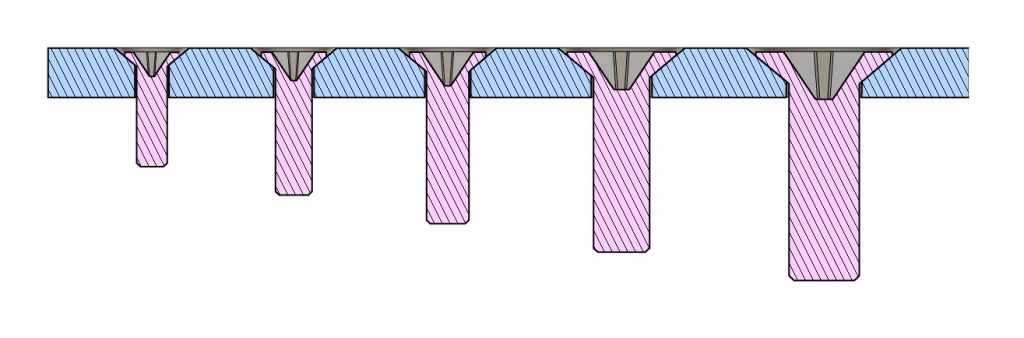

Hole Design Considerations

When implementing countersunk holes, it’s important to consider the following:

- Material thickness and material properties and potential for stress concentrations

- Correct countersink angle (typically 82°, 90° or 100°)

- Depth or diameter of countersink to ensure proper fastener seating

NAS1102 CSK SCREWS

| Fastener | Pin Diameter | Thru Hole Diameter | Thru Hole Diameter Tolerance | CSK Diameter | CSK Diameter (0.5mm sub-flush) | CSK Diameter Tolerance | CSK Angle | Min Section Thickness |

|---|---|---|---|---|---|---|---|---|

| #6 | 3.51 | 3.85 | +/-0.05 | 7.20 | 8.40 | +/-0.1 | 100 deg | 3.00 |

| #8 | 4.17 | 4.50 | 8.55 | 9.75 | 3.25 | |||

| #10 | 4.83 | 5.15 | 9.90 | 11.10 | 3.55 | |||

| 1/4 | 6.35 | 6.65 | 13.00 | 14.20 | 4.15 | |||

| 5/16 | 7.94 | 8.25 | 16.25 | 17.45 | 4.85 | |||

ELEVATE YOUR KNOWLEDGE

Check out the links to see:

- Example drawings

See how the information above can be displayed on manufacturing drawings

Leave a Reply

You must be logged in to post a comment.