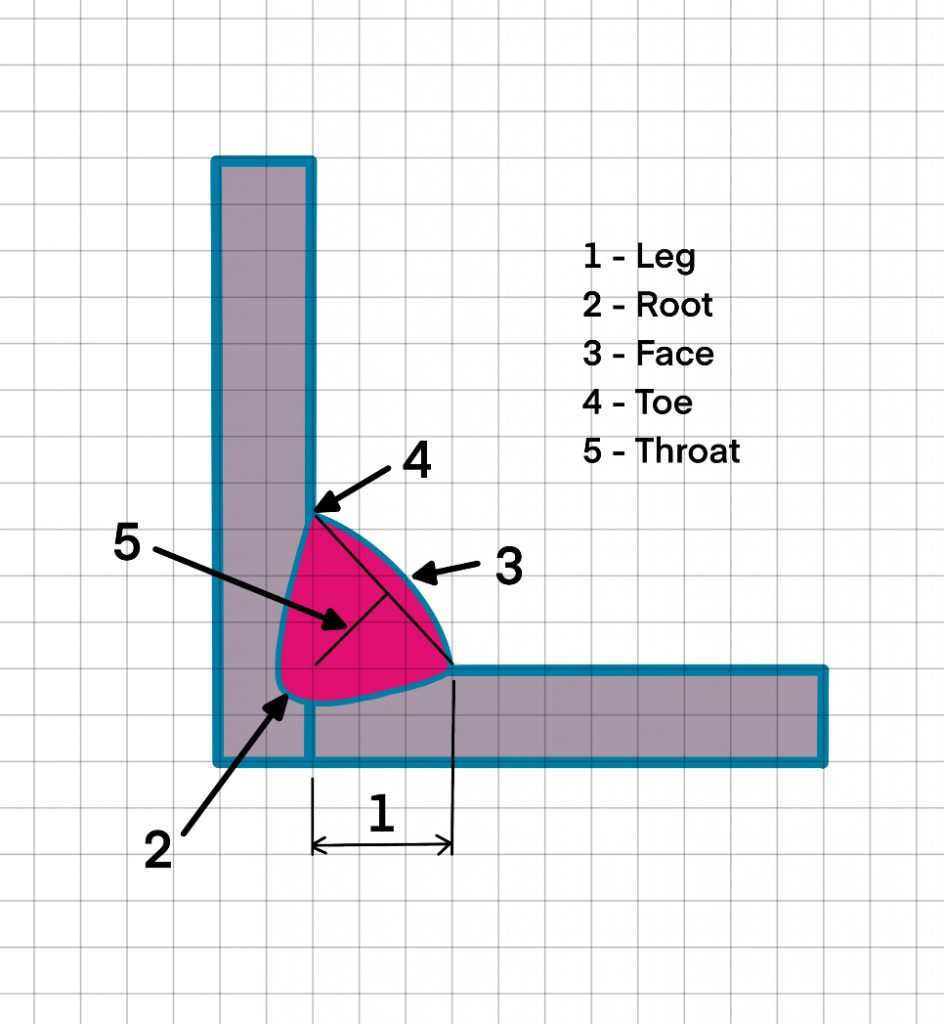

A fillet weld is a type of weld that is used to join two metallic components, typically at right angles to each other, forming an L shape.

The weld is triangular in shape and may have a concave, flat or convex surface depending on the welder’s technique.

It is one of the most common types of welds and is widely used in a variety of industries including: automotive, marine and construction.

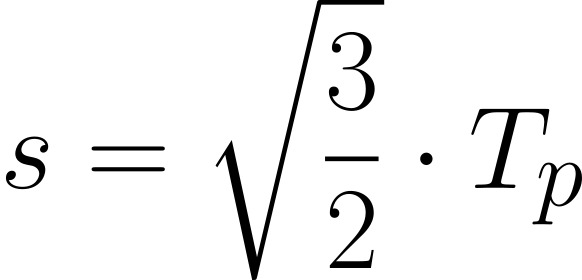

The critical dimension of a fillet weld is the throat (t). However in some standards a fillet weld can be described by its leg length (s).

Care must be taken to ensure the correct dimension is used in the following sizing calculations.

Best Practice/Rule of Thumb

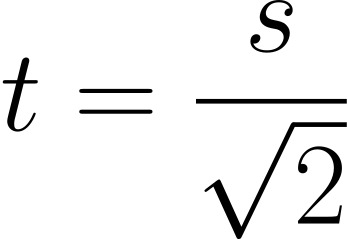

A fillet weld will typically fail in shear across the throat of the weld (t). In order to achieve a full strength weld we would recommend starting your calculations with a weld leg size of:

The fillet weld throat thickness can then be calculated as:

s=weld leg size

Tensile Load Case

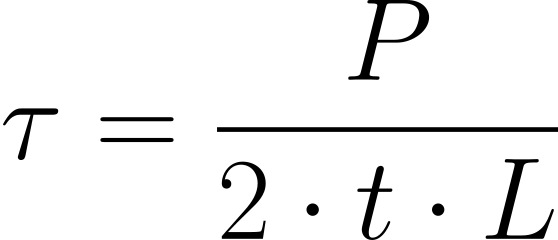

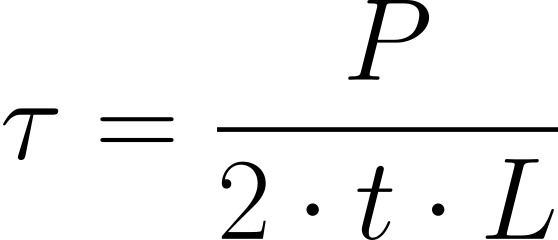

For all the calculations below we have considered a double sized fillet weld connection. If the fillet weld of length L, is loaded by the applied force P the corresponding stress would be:

Shear stress across weld:

L=length of weld

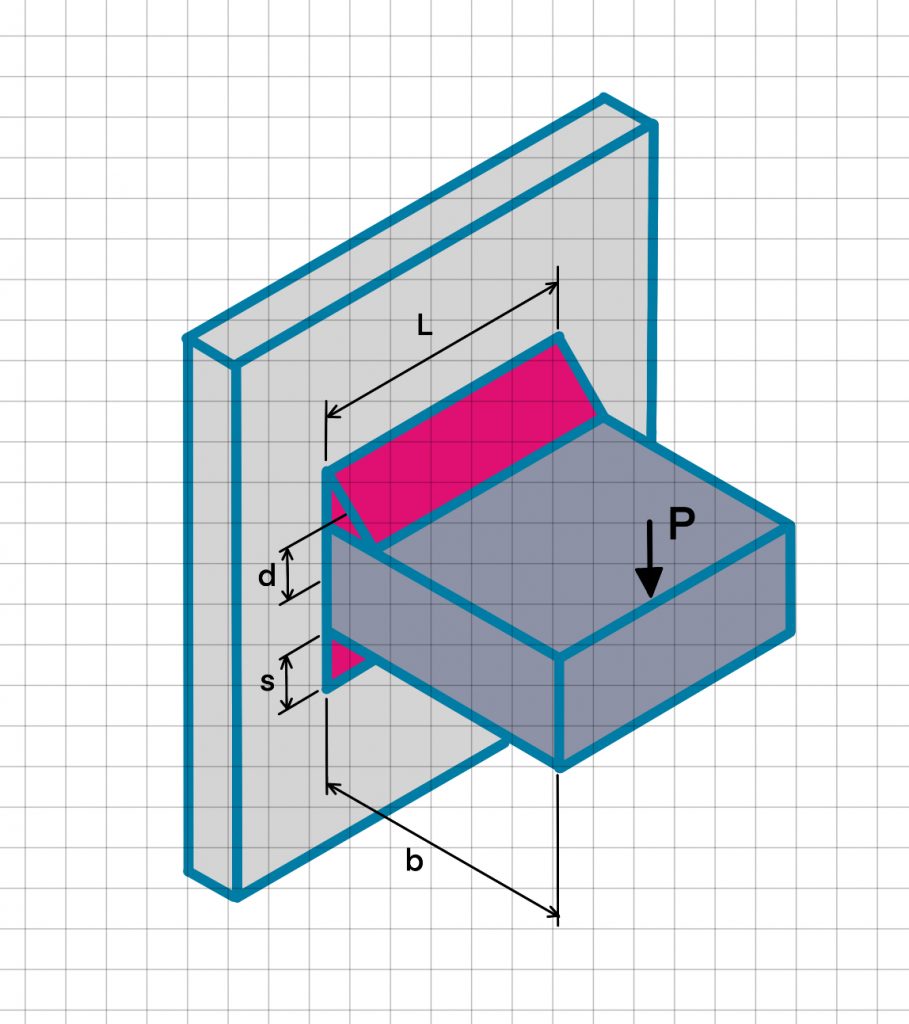

Bending Load Case

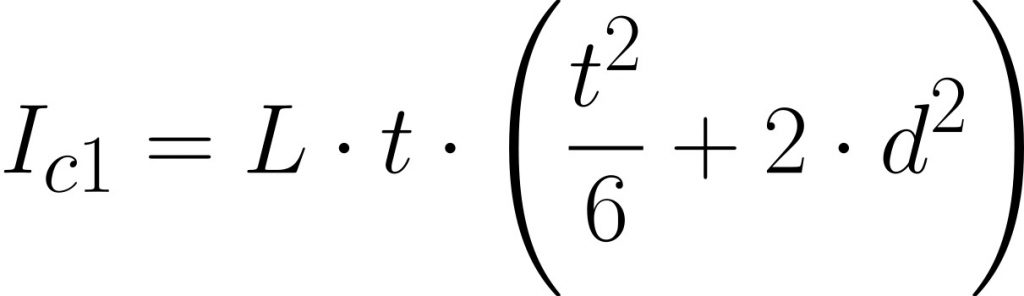

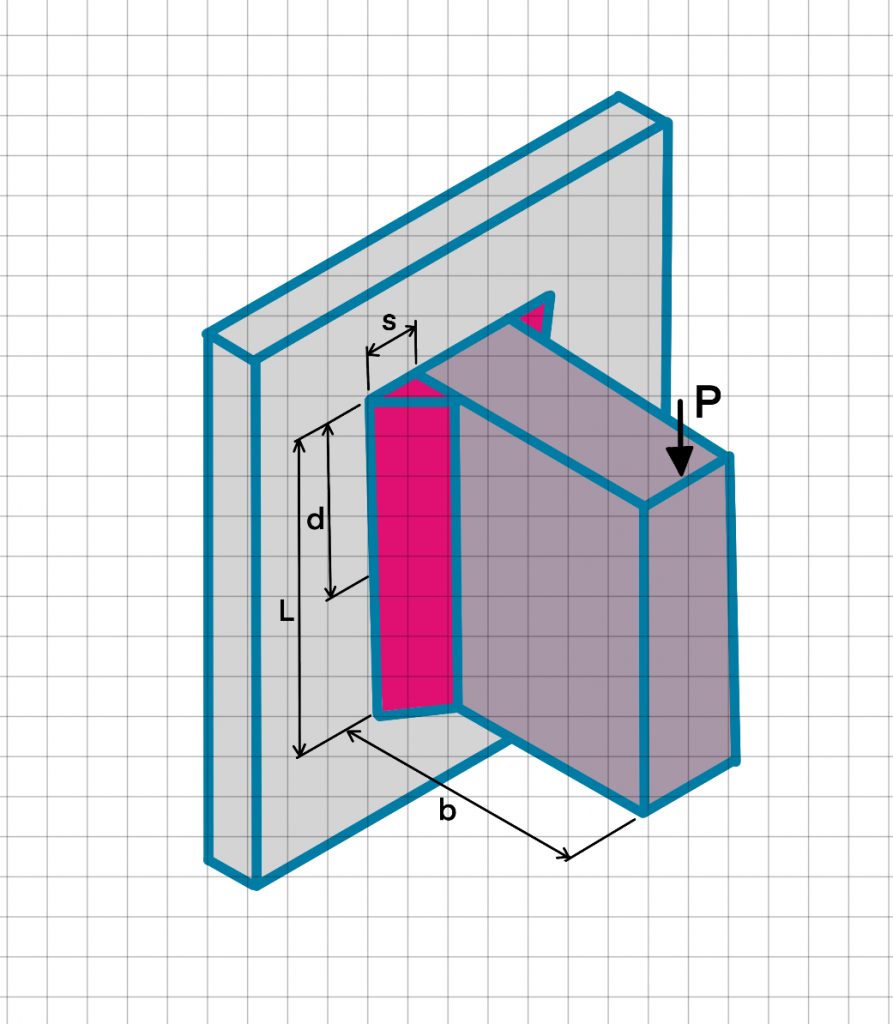

In the following we have considered a fillet weld connection supporting a cantilevered bar carrying a load at its free end.

For this load case we can consider two scenarios: one where the fillet welds are perpendicular to the applied load, and the other where the fillet welds are parallel to the applied load.

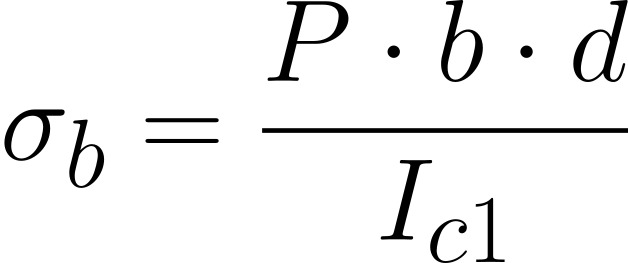

Case 1

Shear stress in weld:

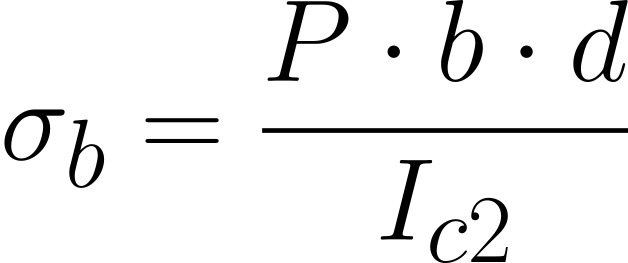

Bending stress in weld:

where I is the second moment of area of the two welds about its centroid:

Case 2

Shear stress in weld:

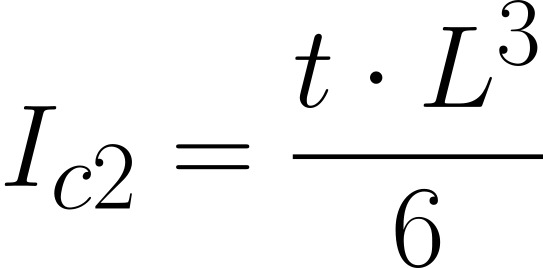

Bending stress in weld:

d=distance from neutral axis

where I is the second moment of area of the two welds about its centroid:

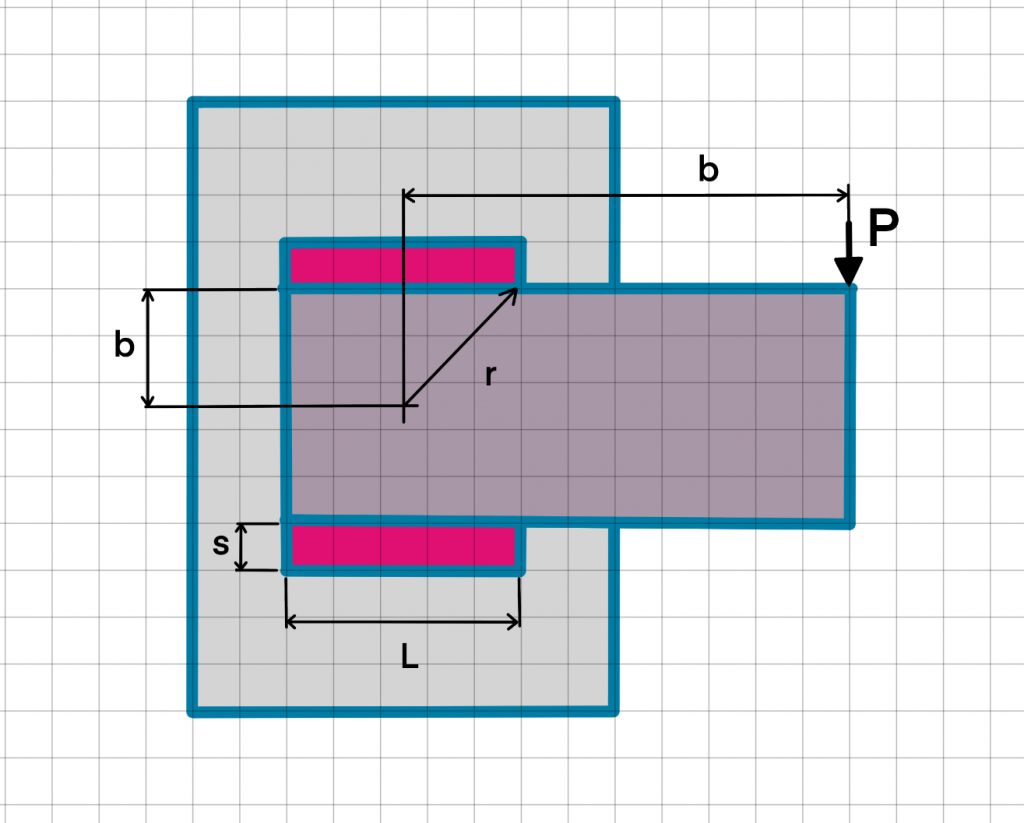

Torsional Load Case

Consider a fillet weld connection carrying an applied load P, as shown below, this will result in both a torsional (torque) and shear force in the weld.

The stresses acting on the weld can be calculated as follows:

Shear stress in weld:

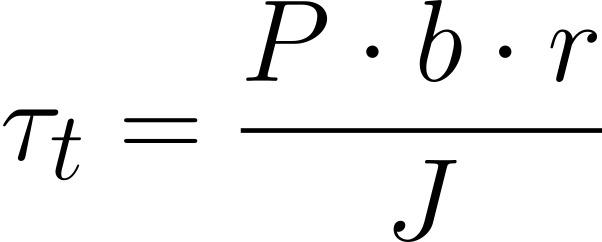

Torsional shear stress in weld:

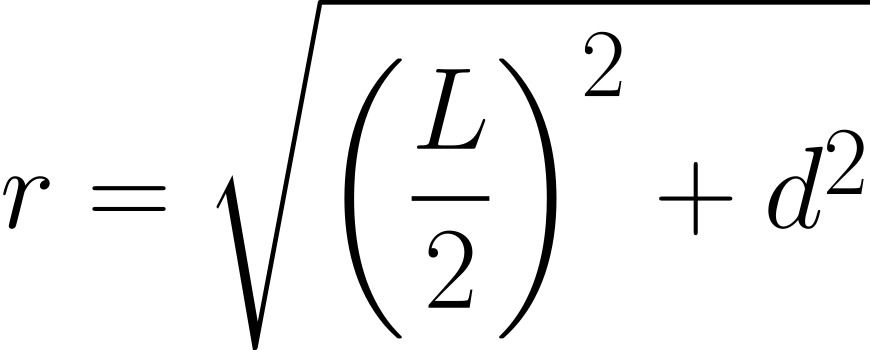

where r is the maximum radial distance of weld to its centroid:

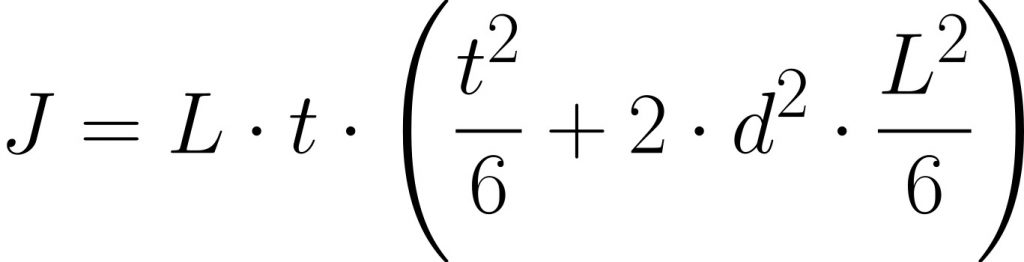

and J is the polar moment of inertia of the two welds about its centroid:

Leave a Reply

You must be logged in to post a comment.