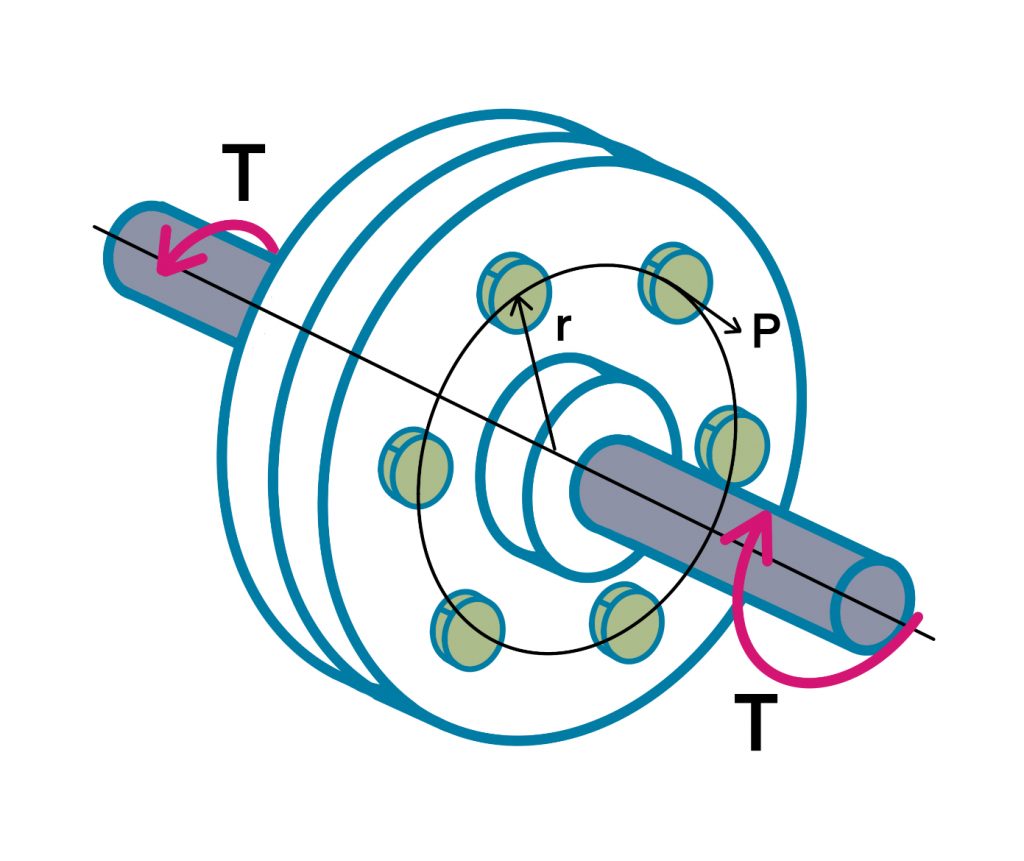

A flanged bolt coupling is a mechanical device used to connect two shafts together at their ends for the purpose of transmitting power.

When connecting shafts using a flanged bolt coupling (like the example shown below) the torque load across the connected shafts generates a shear force in the bolts. In this application, it can be assumed that the shear force is uniformly distributed between all the bolts in the flanged connection.

For any number of bolts Nb, the torque capacity of the coupling can be defined as:

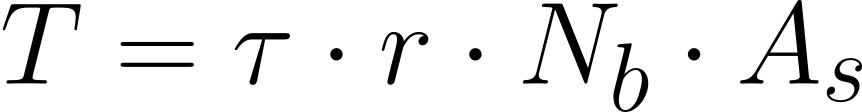

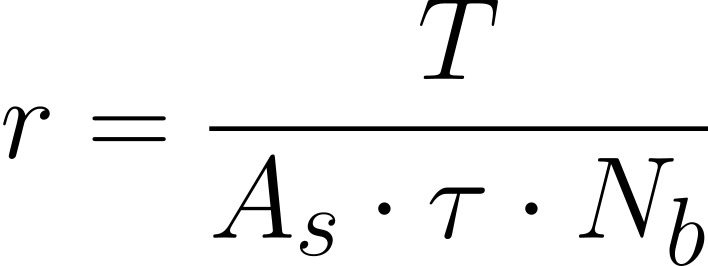

Substituting for load P, and rearranging the equation, we can size our coupling based on certain limiting criteria:

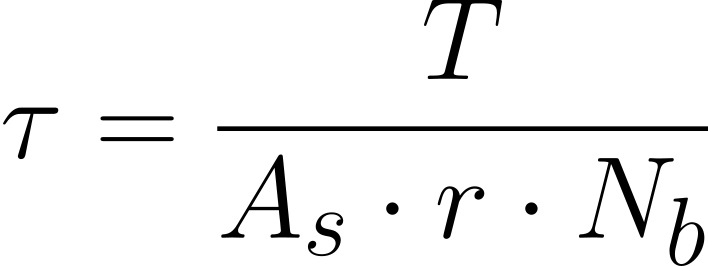

Shear stress in each bolt:

r=radial distance from shaft axis, Nb=number of bolts

Maximum torque load across bolted connection:

Minimum bolt radius to carry know torque:

tau=the allowable shear stress in the bolt,

As=bolt stress area, Nb=number of bolts

Values of stress area for specific bolt sizes can be found on our Sizing Fasteners guide

Leave a Reply

You must be logged in to post a comment.