Standardising hole sizes across engineering designs offers several important advantages:

- Reduced tooling costs – Manufacturing facilities can maintain a smaller inventory of drill bits and cutting tools

- Improved manufacturing efficiency – Machine operators spend less time changing tools and can develop consistent processes

- Enhanced interchangeability – Components from different manufacturers or production runs can be used interchangeably when hole sizes are standardized

- Lower risk of errors – Using standard hole sizes reduces the chance of assembly mistakes or incorrect tooling selection

Imperial Fastener Hole Size

(No Doweling Feature)

| Fastener | Pin Diameter | Hole Size | Hole Tolerance | Positional Tolerance |

|---|---|---|---|---|

| #6 | 3.51 | 3.85 | +/-0.05 | 0.2 |

| #8 | 4.17 | 4.50 | ||

| #10 | 4.83 | 5.15 | ||

| 1/4 | 6.35 | 6.65 | ||

| 5/16 | 7.94 | 8.25 | ||

| 3/8 | 9.53 | 9.85 | ||

| 1/2 | 12.70 | 13.00 |

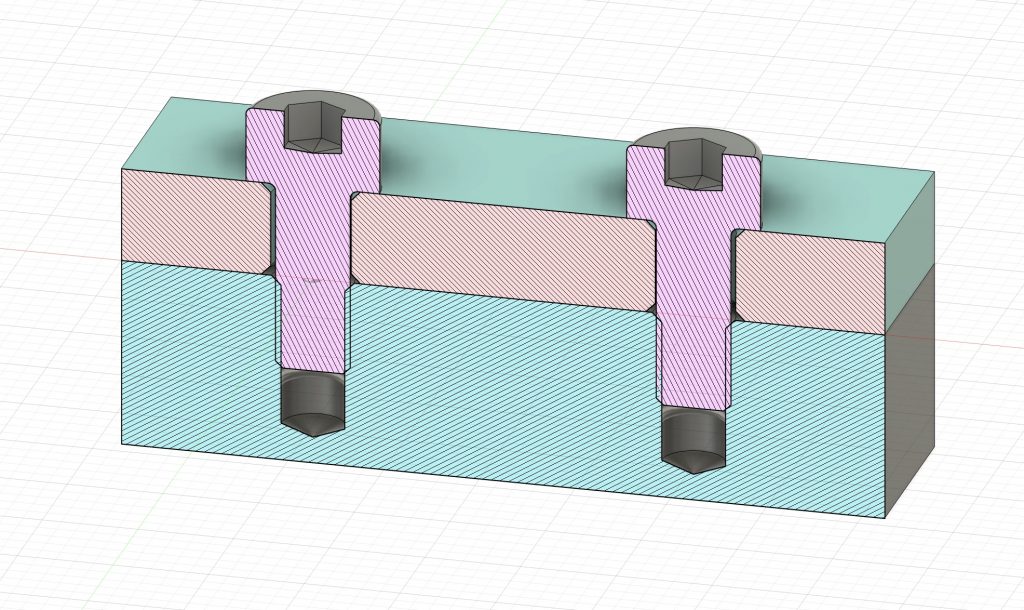

Imperial Fastener Hole Size

(with Doweling Feature)

| Fastener | Pin Diameter | Hole Size | Hole Tolerance | Positional Tolerance |

|---|---|---|---|---|

| #6 | 3.51 | 4.00 | +/-0.05 | 0.2 |

| #8 | 4.17 | 4.65 | ||

| #10 | 4.83 | 5.30 | ||

| 1/4 | 6.35 | 6.80 | ||

| 5/16 | 7.94 | 8.40 | ||

| 3/8 | 9.53 | 10.00 | ||

| 1/2 | 12.70 | 13.15 |

ELEVATE Your knowledge

Check out the links to see:

- How are these tolerances are calculated?

A breakdown of tolerance stack ups calculating the hole size and geometric positional tolerance required. - Example drawings

See how these numbers should be displayed on manufacturing drawings

Leave a Reply

You must be logged in to post a comment.