Mechanical Design

Click on the links below to learn more about each subject

Design Guides

Slip Fit vs Press Fit

Understanding engineering limits and fits are a staple for every engineer in order to create well functioning mechanical assemblies. In this article we are going to focus on slip fit vs press fit. What are the key differences, the advantages and disadvantages of both and some practical examples.

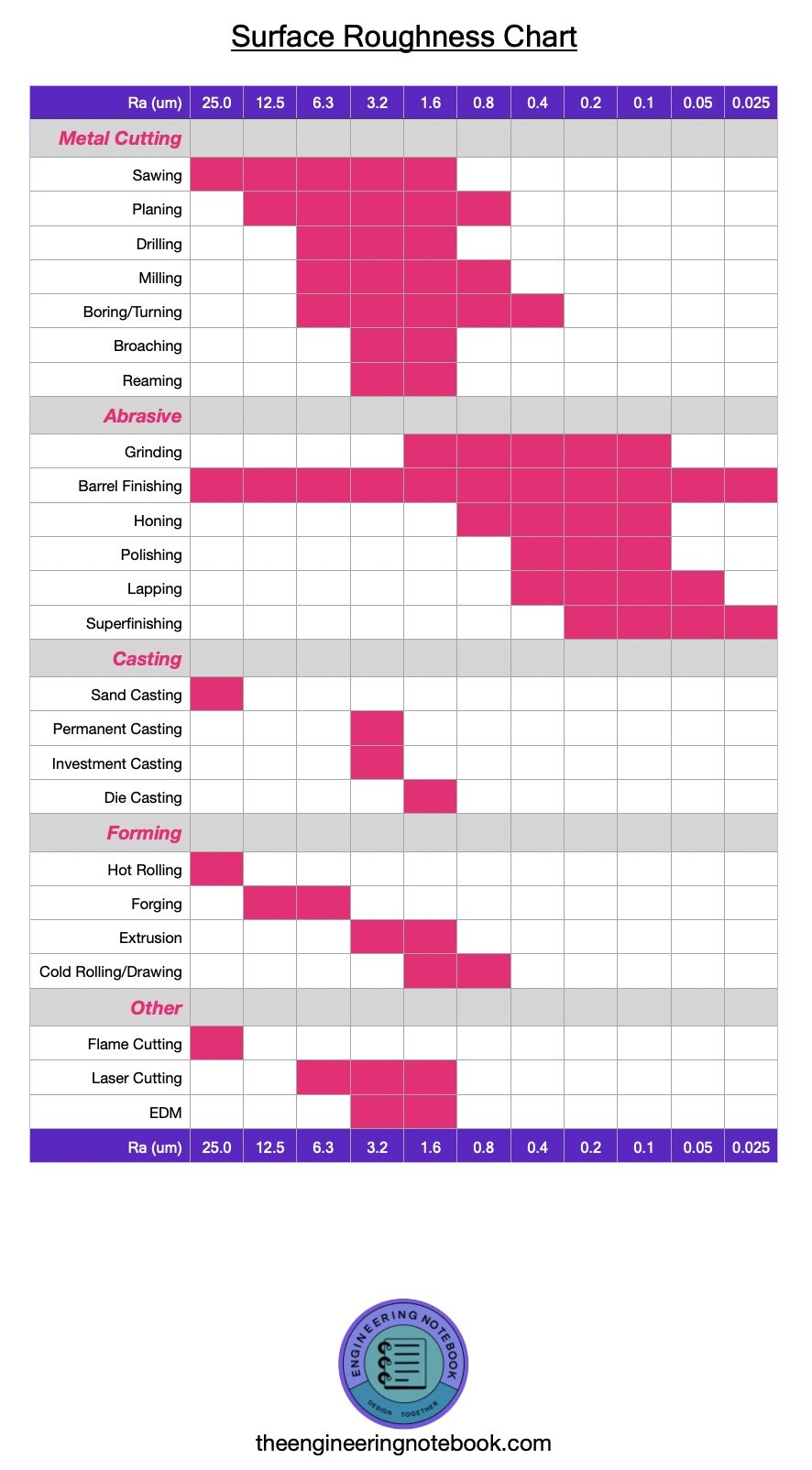

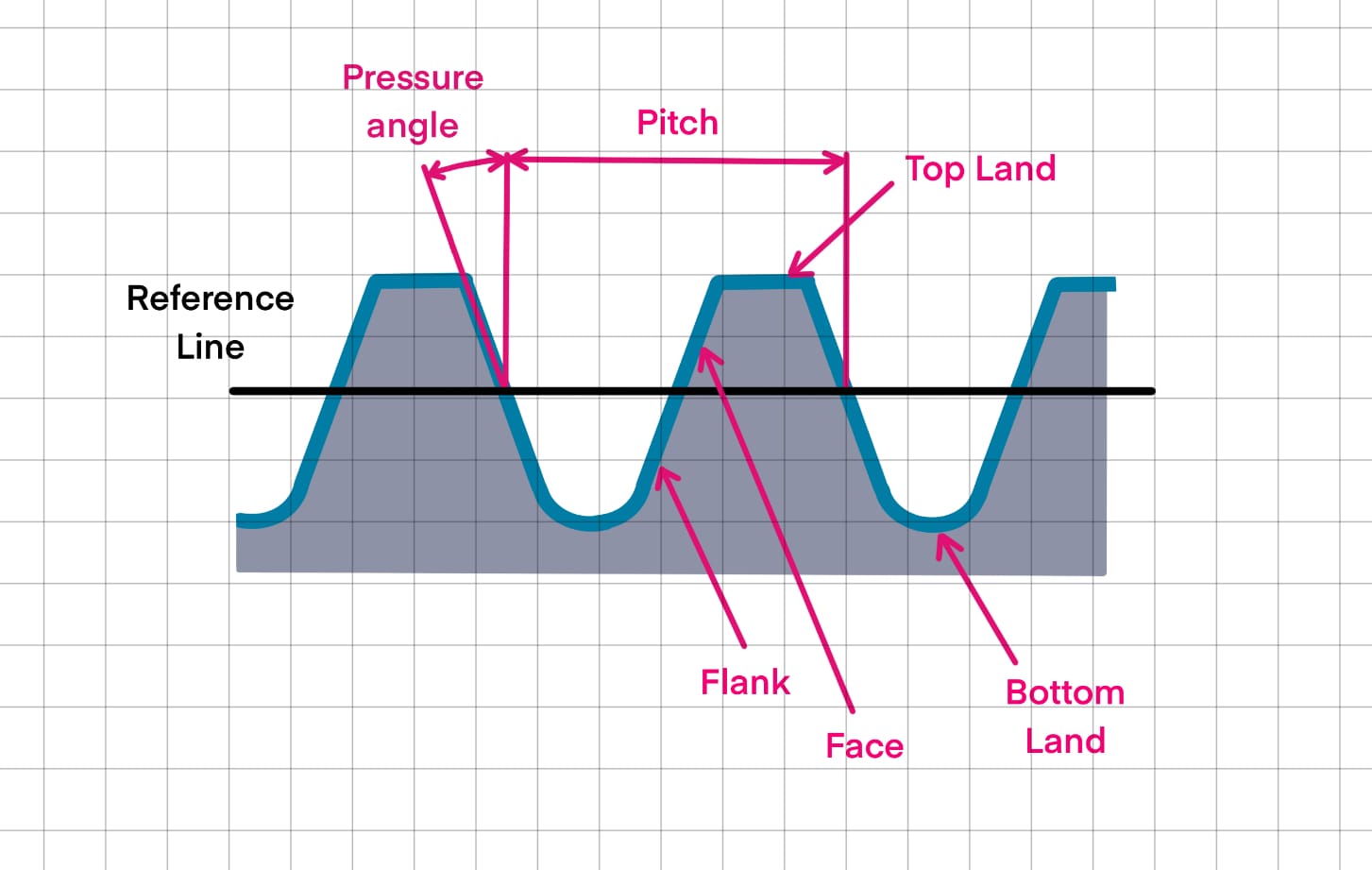

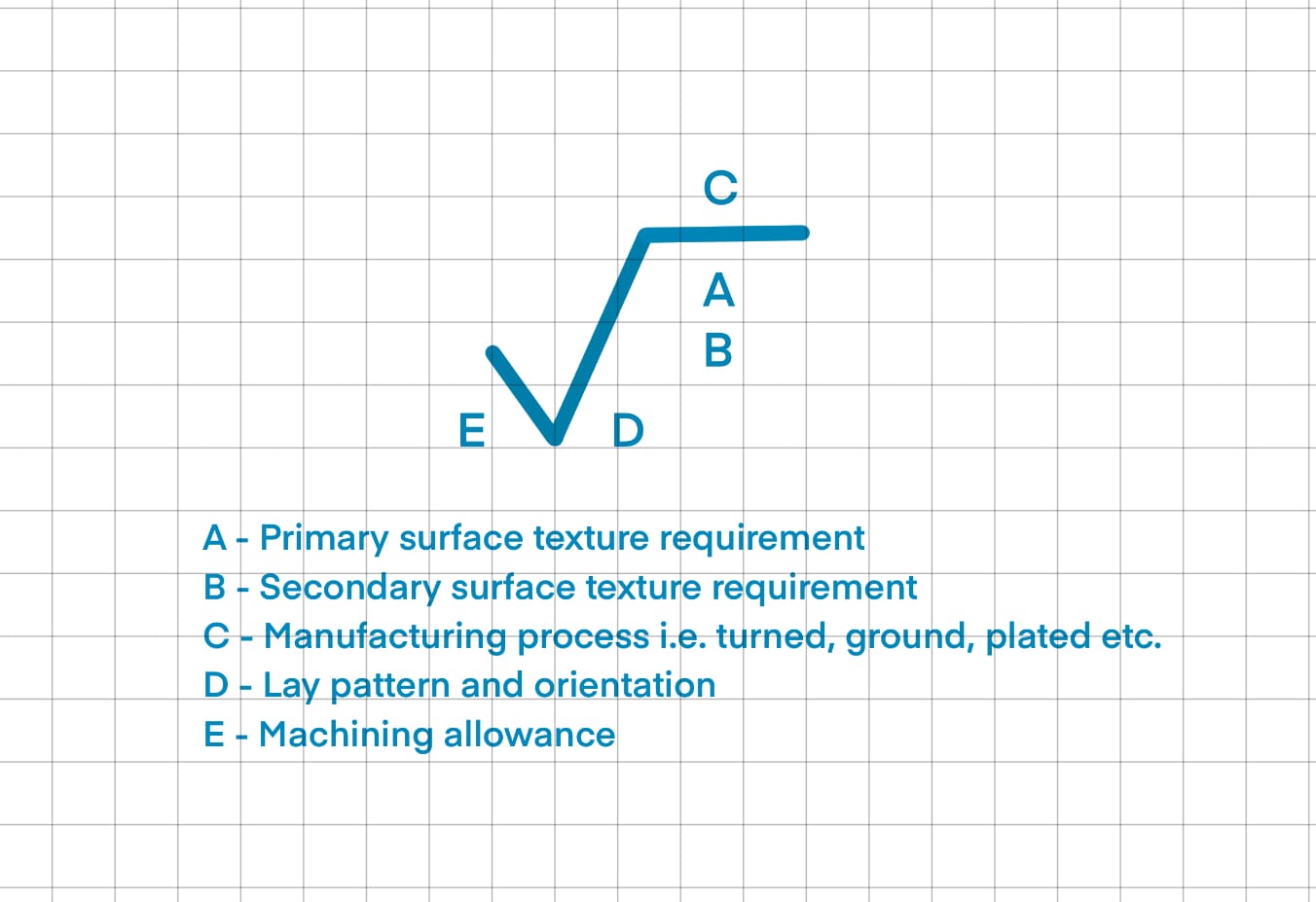

The FUNDAMENTALS of surface finish

Surface finish describes texture requirements for surfaces, including roughness, waviness, and lay. Symbols on technical drawings specify these textures and necessary manufacturing processes, helping to avoid extra costs and delays.

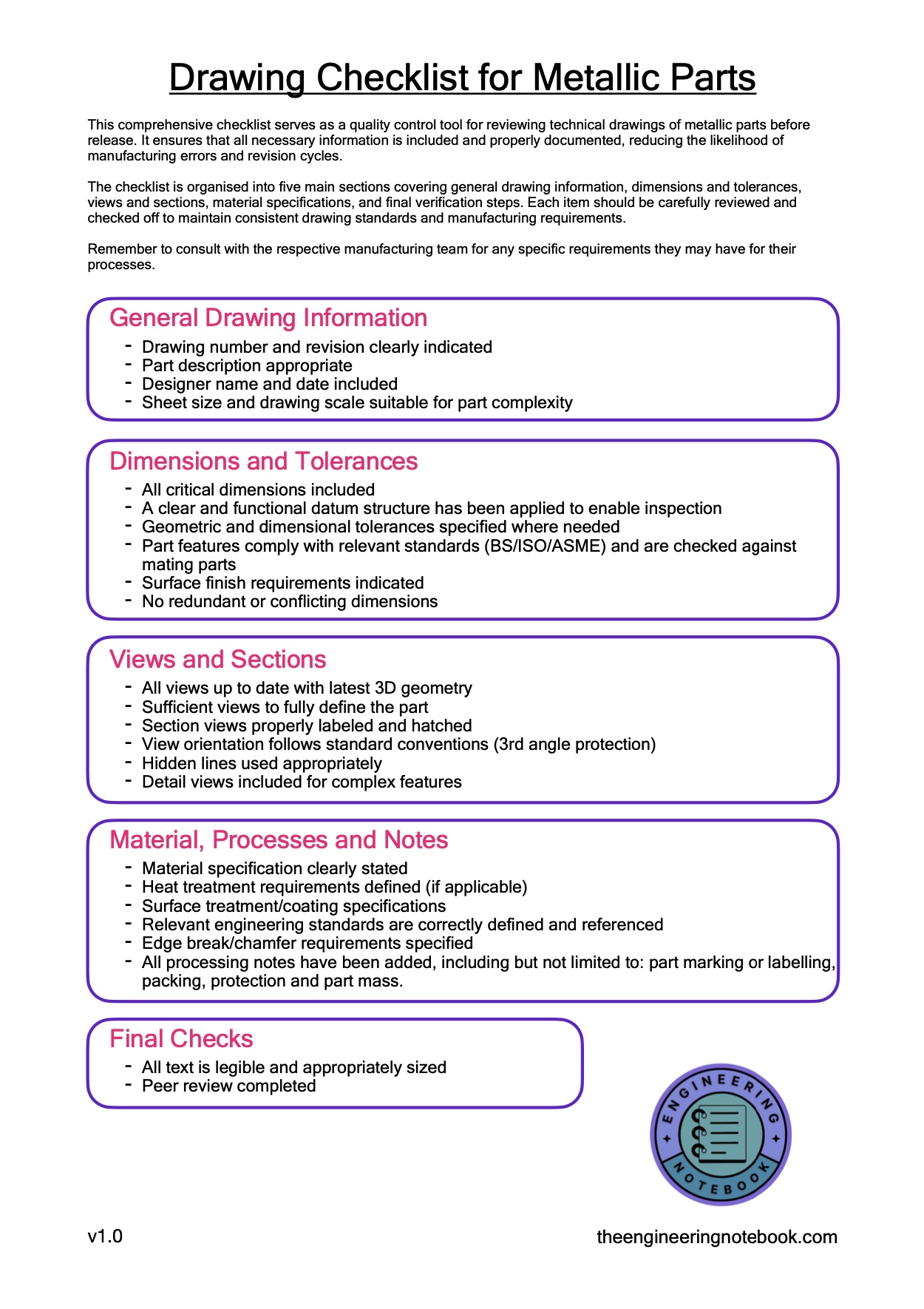

Technical Drawing Checklist for Metallic Parts

This comprehensive checklist provides a systematic approach to reviewing technical drawings of metallic parts before release, covering all essential aspects from general information and dimensions to material specifications and final verification steps.

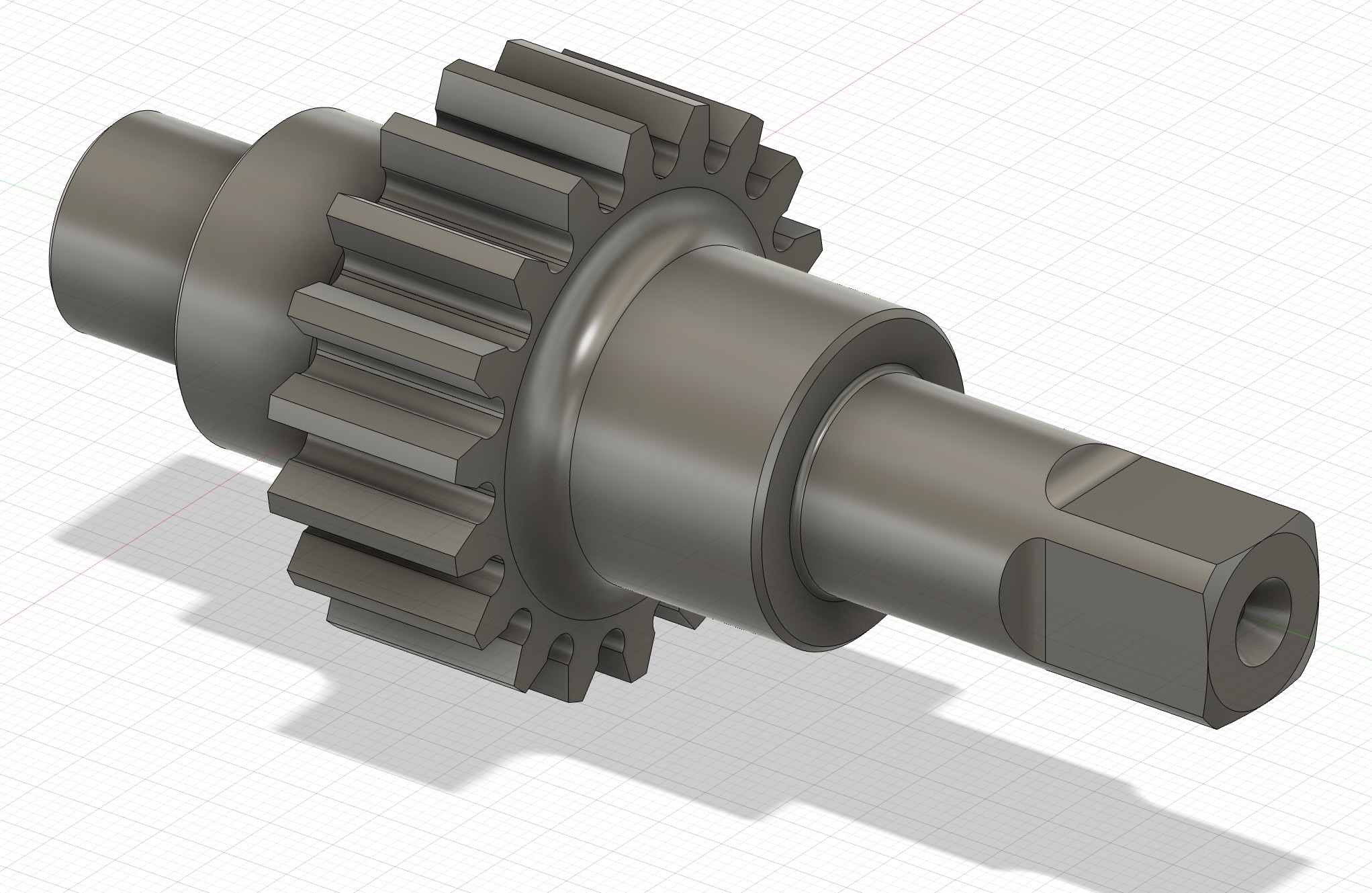

Gears

Metallic Processes

Pickling

Pickling is a metal cleaning process using acidic baths to remove impurities. It’s simple, affordable, and improves corrosion resistance. While effective, it has drawbacks like solution degradation and hazardous waste production.

Passivation

Passivation builds a protective layer on metal surfaces, enhancing corrosion resistance. It’s vital for stainless steel, restoring protection after fabrication.

Shot Peening

Shot peening is a crucial metal treatment process that enhances the fatigue resistance, durability, and surface hardness of components. This technique involves firing small beads at high velocity onto a material’s surface, inducing compressive stress and improving mechanical properties.